The Essential Guide to Reverse Logistics for the Retail Industry

Reverse logistics has emerged as a critical component of supply chain management, especially in the retail sector. As consumer expectations rise and sustainability takes center stage, reverse logistics professionals face mounting pressure to optimize processes for returned inventory while minimizing waste and costs.

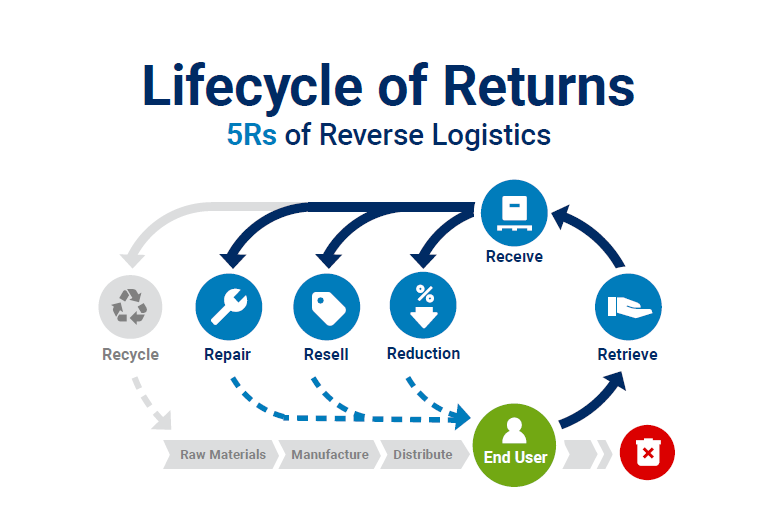

This guide explores the fundamentals of reverse logistics in retail, addressing common concerns such as accelerating inventory movement, maximizing returns value, optimizing the supply chain, boosting efficiency/improving velocity, dispositioning strategy, and reducing environmental impact. We’ll cover key processes, challenges, examples, benefits, and sustainability practices—all while adhering to the five Rs framework.

What Is Reverse Logistics?

Reverse logistics refers to the process of moving goods from their final destination back through the supply chain for the purpose of returns, refurbishment, recycling, or disposal. In retail, this often involves handling customer returns, overstock, or defective products. Unlike forward logistics, reverse logistics requires systems that account for variability, such as the condition of goods, customer expectations, seasonal fluctuations, and complex return flows.

Reverse logistics is no longer just a cost center for retailers; it’s a strategic function that enhances profitability, strengthens customer relationships, and supports sustainability goals. By addressing common challenges and leveraging modern tools and practices, retail professionals can unlock significant value from returned inventory while minimizing waste.

For retail reverse logistics professionals, the key lies in continuous improvement—optimizing processes, embracing technology, and aligning with sustainability trends to stay ahead in a competitive market.

The Process of Reverse Logistics in Retail

- Return Initiation: Customers initiate a return through online portals, in-store drop-offs, or customer service centers.

- Inspection and Sorting: Products are inspected to determine their condition—whether they can be resold, refurbished, or recycled.

- Disposition: Items are routed to appropriate destinations, such as resale channels, donation programs, recycling facilities, or waste management.

- Restocking or Recycling: Goods deemed suitable for resale are restocked; others are refurbished or sent for material recovery.

- Data Analysis: Performance metrics are tracked to improve efficiency and reduce future returns.

Common Challenges in Reverse Logistics

- Cost Management: Handling, shipping, and restocking costs can erode margins.

- Inventory Visibility: Tracking returns across multiple locations and systems is complex.

- Customer Expectations: Fast refunds and transparent return policies create operational strain.

- Sustainability Goals: Reducing landfill contributions and meeting corporate social responsibility targets requires innovative solutions.

- Process Standardization: Ensuring consistent practices across distributed retail locations is difficult.

Benefits of Optimized Reverse Logistics

- Increased Recovery Rates: Reselling refurbished or lightly used items unlocks maximum value.

- Improved Velocity: Faster processing and fewer touches reduce labor costs and free up resources.

- Improved Customer Loyalty: Easy returns foster trust and repeat business.

- Reduced Environmental Impact: Recycling and reuse initiatives divert waste from landfills.

- Enhanced Data Insights: Analytics drive smarter inventory and supply chain decisions.

The Five Rs of Reverse Logistics

Returns: Managing returned goods from customers.

Repair/Refurbishment: Repairing or restoring items for resale.

Recycling: Recovering materials for reuse.

Resale: Selling products through secondary markets.

Reduction: Minimizing the volume of returns through better customer education and product quality.

Sustainability in Reverse Logistics

Sustainability is a cornerstone of effective reverse logistics. Retailers are adopting practices such as:

- Partnering with recycling programs to process defective or unsellable goods.

- Implementing take-back programs that allow customers to return used items for recycling.

- Reducing emissions by consolidating shipments and using eco-friendly packaging.

- Tracking carbon footprints and setting reduction targets for reverse supply chain activities.

Like to learn more? Do you have excess to sell? Fill out the contact form for a complimentary review of your reverse logistics operation and we’ll get back to you promptly.

Helpful Links

- Recovery & Efficiency: Are Retailers Poised for Reverse Logistics Success? – Liquidity Services

- Mastering Reverse Logistics: The Critical Role of Dispositioning Strategy for Retailers – Liquidity Services

- Sustainable Reverse Logistics: Greening Your Supply Chain – Liquidity Services

- Liquidation Strategies: Pros and Cons of Auctions – Liquidity Services

- Reverse Logistics: How to Get Maximum Recovery from Customer Returns – Liquidity Services

- Seller Case Studies – Liquidity Services

Comments are closed.